Your Trusted

Partner

Make it with Objective 3D

This Is Objective 3D

Objective3D is Australia and New Zealand’s leading provider of Stratasys, GE Additive, Lithoz and Artec 3D Printer and 3D Scanner Solutions for designers, educators and manufacturers.

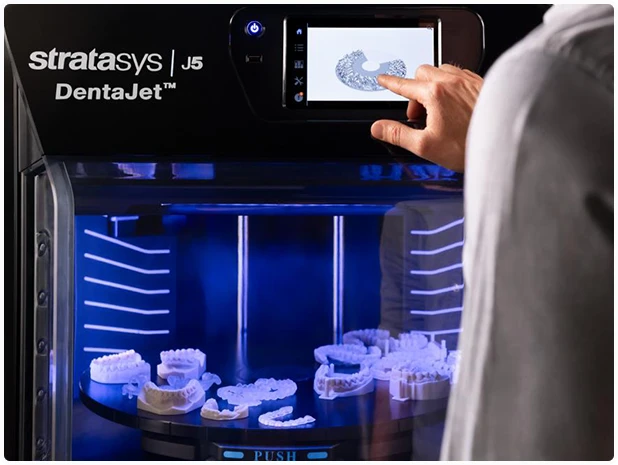

As the preferred Stratasys Partner, Objective3D provides both 3D Printer Solutions and 3D Printing Bureau Service all through a state-of-the-art Additive Manufacturing Centre which houses the most extensive range of Fused Deposition Modelling (FDM), PolyJet, SLS, DMLS and BMD Machines including consumables and spare parts.

A Full Fledged Fleet Of 3D Printing Technology

Awards & Accreditations

Stratasys Customer Satisfaction and Support Award (2013)

Stratasys Customer Satisfaction and Support Award (2015)

Stratasys Global Partner

ISO 9001 Certified

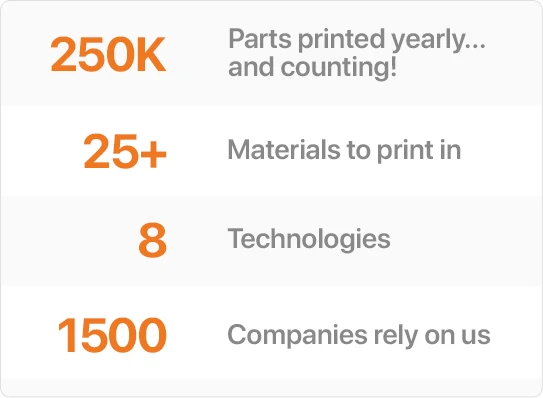

The Largest Service Bureau In Australia & New Zealand

Objective3D Service Bureau is helping companies in diverse industries create exceptional new products at every phase of the production process including one-off parts, low-run production, and complete assemblies, utilising additive and subtractive prototyping and manufacturing processes.

Supported by the Stratasys Direct Manufacturing Global Network the service bureau with 16 commercial 3D printer grade machines provides the broadest range of 3d printing technologies including materials and backed by qualified engineers.

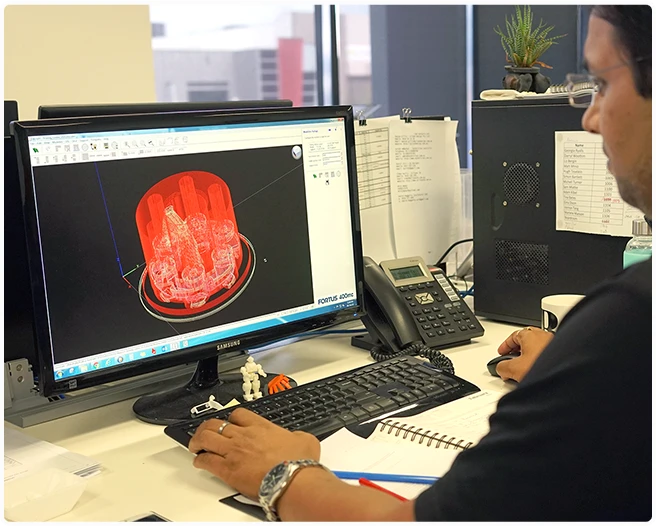

We Practice What We Preach - Daily Users Of The Technology

The thing that truly makes us special is that we are daily users of the technology. Thanks to our service bureau, our team of application engineers work with the technology every day, printing new parts to see how the technology can be used in various ways. This gives us the ability to offer the perfect solution to our customers based their specific requirements. Our deep knowledge of 3D printing technology is what truly sets us apart from other companies and makes us the perfect partner for your engineering and design needs.

Powered By The Best

The team at Objective 3D is a hand picked group of highly skilled and experienced engineers, who are driven to help manufacturers innovate and grow. They have a passion for 3D printing and are constantly exploring for new ways in which businesses benefit from adopting this technology. They are truly out-of-the-box thinkers, which makes them an invaluable asset to any company that is looking to stay ahead of the competition.

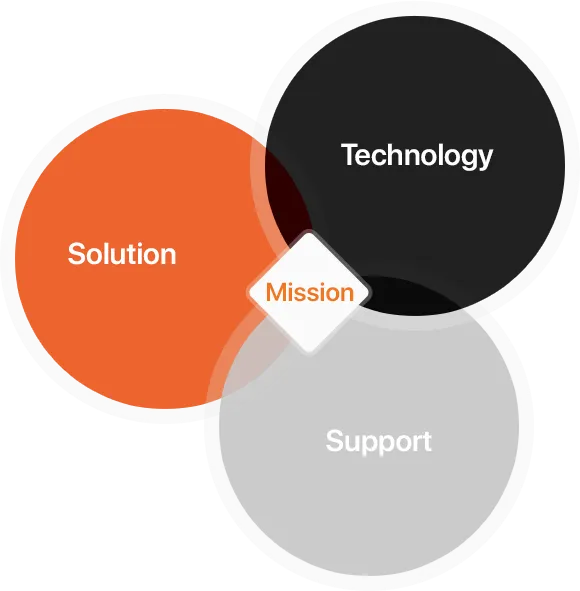

Our Mission Is To Revolutionise The Way Businesses Manufacture Today, So You Can Build A Better Tomorrow

A Company Dedicated To Helping You Innovate Through 3D Printing

Click on the following to learn more about each of our focus areas.

Objective 3D

Headquarters

Located in Carrum Downs, Victoria, Australia –

Our HQ is a state-of-the-art facility that features a workshop, showroom, service bureau, part finishing facility, offices, and training centre.

We’re open Monday to Friday 8:30am – 5pm.

Drop in and see us today!

General Enquiries

Talk To An Expert

Our team of application and industry engineers are here to help. We can answer any questions you about range of materials, printing applications, or features of the printer. If we feel there is a more optimal solution that suits your requirements, we will recommend it. Talk To An Expert Today!