Big Bang Upgrade: Up to 30% Trade-in Discount

Limited Time Offer: SAVE with METHOD X and METHOD XL Bundles.

- 3D Printers

- 3D Printers

- FDM

- Polyjet

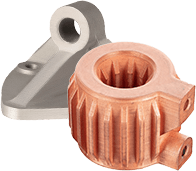

- Metal

- Ceramic

- DLP

- SAF

- View all

- Professional Entry Solutions

- Large Team Solutions

- Carbon Filled Solutions

- Production Solutions

- Professional Entry Solutions

- Production Solution

- Medical & Dental Solutions

- Professional Entry Solutions

- Medium Size Production

- Large Size Production

- Entry Level Ceramics

- Advanced Ceramics

- DLP 3D Printer

- SAF 3D Printer

- 3D Scanners

- 3D Scanners

- Large Parts with Big Data Sets

- Small Parts with High Accuracy

- Fully Mobile Scanning

- Large Parts with Big Data Sets

- Small Parts with High Accuracy

- Fully Mobile Scanning

- Long-Range Scanning

- Materials

- High Performance Materials

- View All

- Industries

- ApplicationApplications

- Manufacturing

- Rapid Prototyping

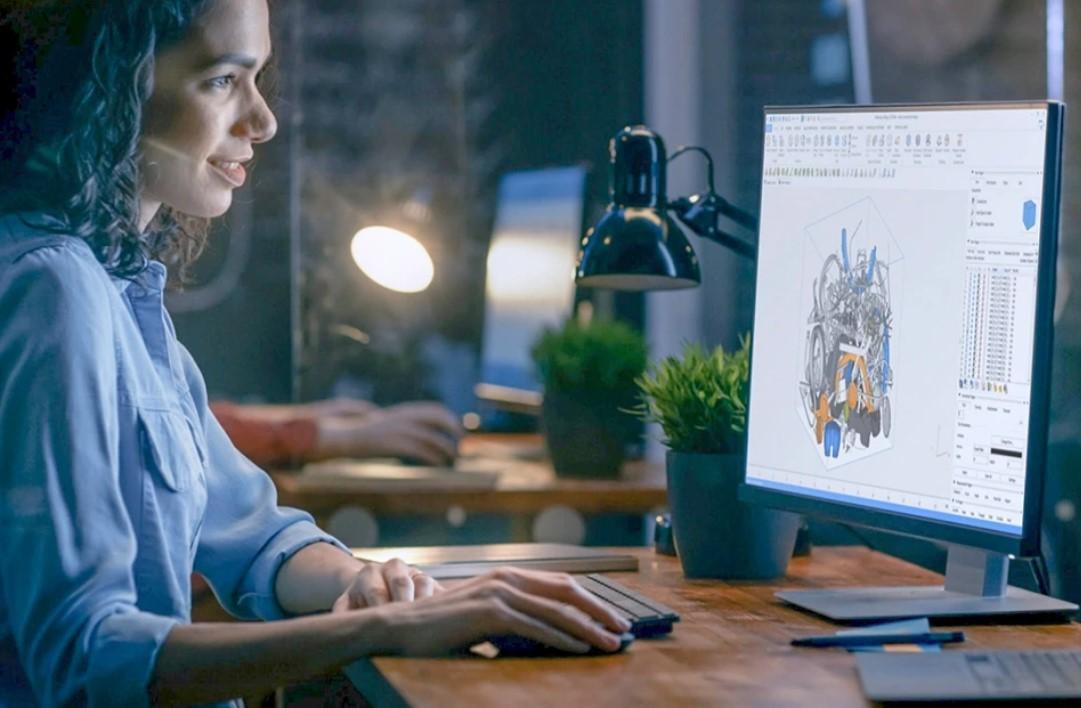

- SoftwareSoftware

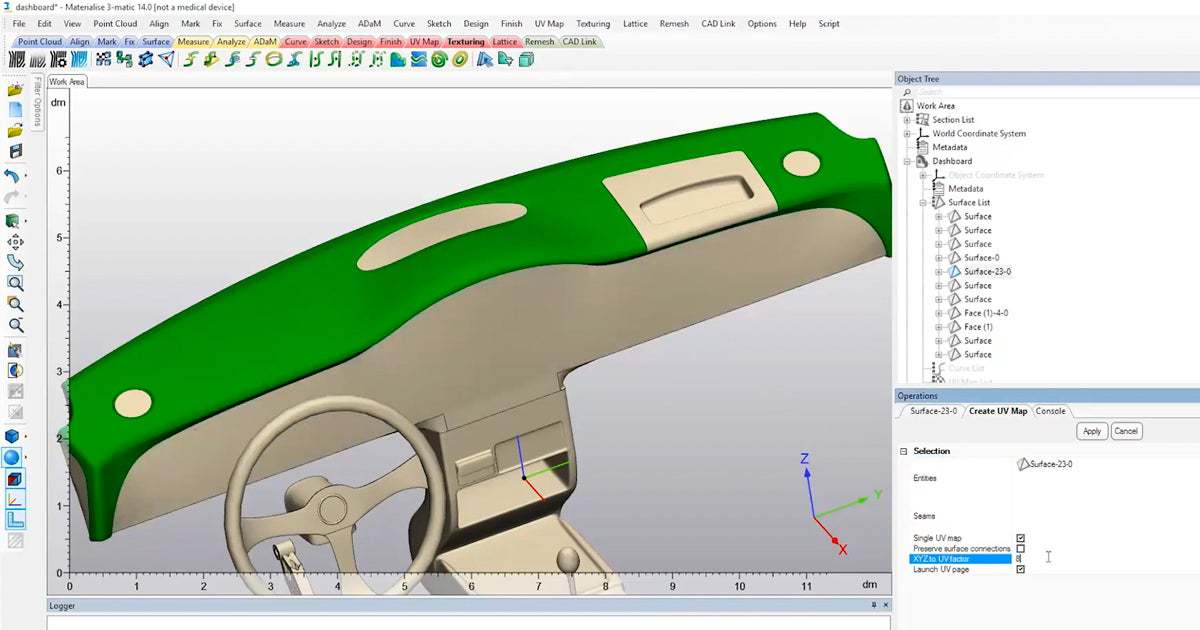

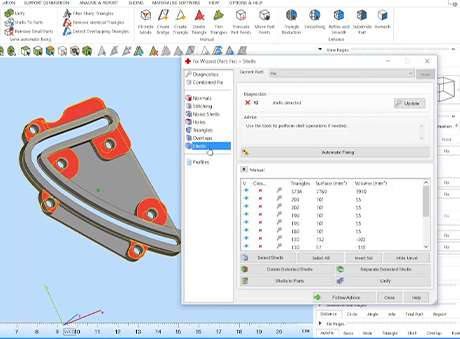

- Data Prep and STL Editor

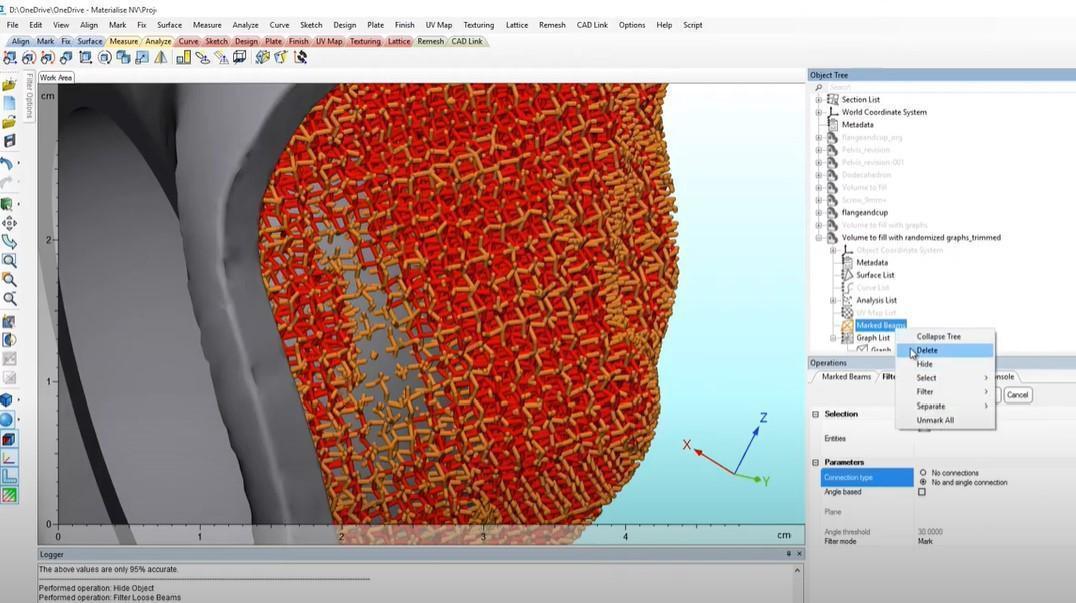

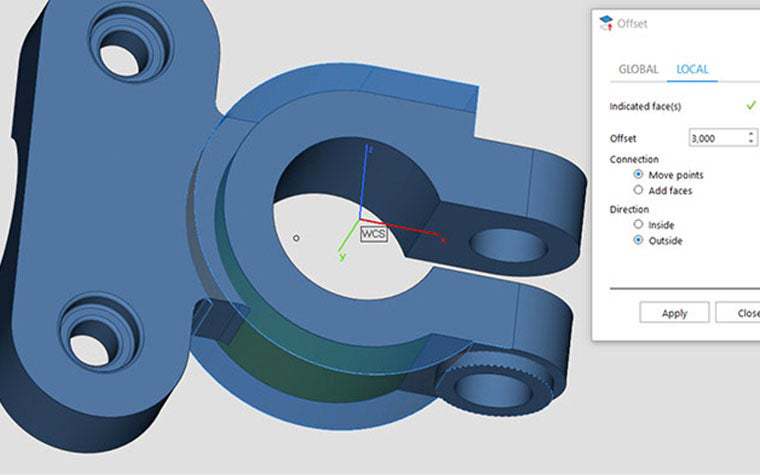

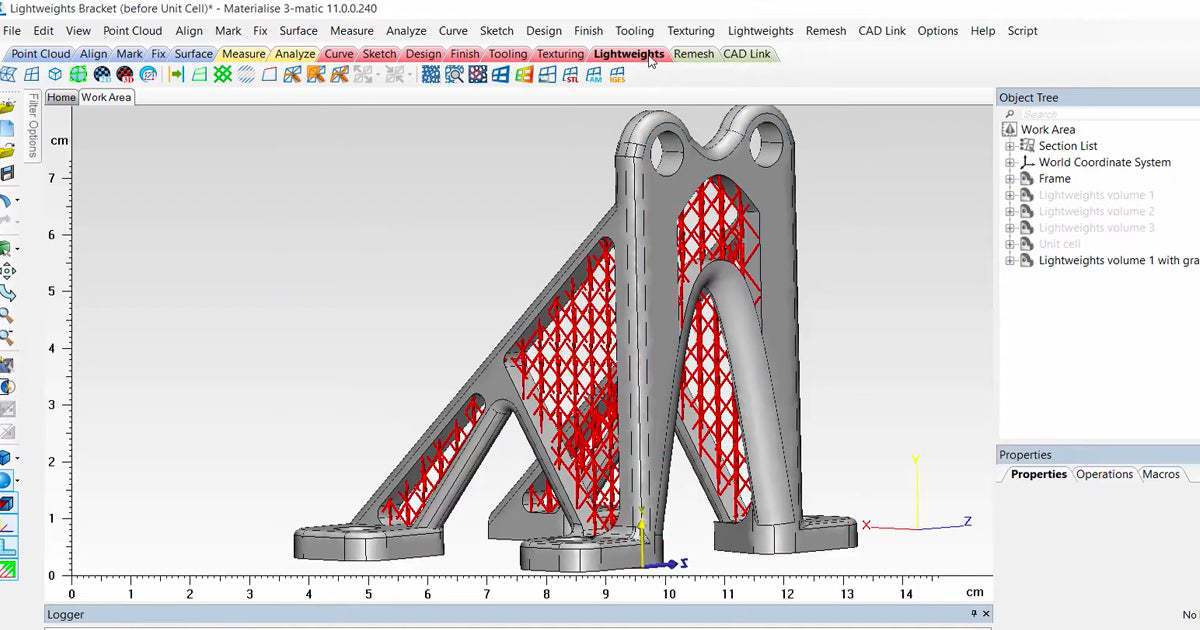

- Design Optimisation for AM

- Slicing Software

- Work Order Management

- 3D Printing Academy3D Printing Academy

Academy

Solutions

- Company