Direct Metal Laser Sintering Materials

Metal powder materials are at the first step toward high-quality results. Through extensive testing and validation, Concept Laser metal powders are highly optimized for the LaserCUSING® process, and when paired with it’s corresponding parameter sets, will yield results that meet the highest industry standards.

| Material | Description | Ultimate Tensile Strength | Yield Strength | Elongation at Break | Modulus of Elasticity | Hardness | Maximum Operating Temperature | Thermal Conductivity | Conductivity Coefficient of Thermal Expansion (CTE) |

Stainless Steel 17-4 PH | Excellent weld-ability & corrosion resistance; Cost effective | 142 ± 7 ksi (980 ± 50 MPa) | 73 ± 7 ksi (500 ± 50 MPa) | 25 ± 5% | 25 ± 3 msi (170 ± 20 GPa) | 230 ± 20 HV1 | ~1022 °F (~550 °C) | 97 Btu in/(h ft2 °F/in) (14 W/m°C) | 7.8 x 10-6 in/in°F (14 x 10-6 m/m°C) |

Stainless Steel 316L | Excellent weld-ability, corrosion resistance & ductility | 93 ± 7 ksi (640 ± 50 Mpa) | 77 ± 8.7 ksi (530 ± 60 Mpa) | 40 ± 15 % | typ. 85 HRB | ||||

Aluminum AlSi10Mg | Low weight, high strength, & good thermal properties | 49 ± 6 ksi (340 ± 40 Mpa) | 36 ± 2 ksi (250 ±15 Mpa) | 1.5 ± 0.5 % | 120 ± 5 HBW | ||||

Inconel 625 | High tensile, creep and rupture strengths | 130 ksi ± 7 ksi (900 ± 50 MPa) | 89 ksi ± 7 ksi (615 ± 50 MPa) | 42 ± 5% | 20.3 msi ± 3 msi (140 ± 20 GPa) | ~30 HRC (287 HB) | ~1200 °F (~650 °C) | ||

Inconel 718 | Good tensile, creep & rupture strength; Fatigue resistance | 142 ± 7 ksi (980 ± 50 MPa) | 92 ± 7 ksi (634 ± 50 MPa) | 31 ± 5% | ~30 HRC (287 HB) | ~ 1200 °F (~650 °C) | 6.9 – 7.2 x 10-6 in/in°F (12.5 – 13 x 10-6 m/m°C) |

||

Titanium Ti64 | Biocompatible; Corrosion resistance | 166 ± 9 ksi (1,150 ± 60 MPa) | 150 ± 10 ksi (1,030 ± 70 MPa) | 11 ± 2% | 16 ± 1 msi (110 ± 7 GPa) | ~400 – 430 HV (41 – 44 HRC) | ~660 °F (~350 °C) | ||

Cobalt Chrome CoCrMo | High tensile strength & hardness; Biocompatibility | 174 ± 22 ksi (1,200 ± 150 MPa) | 116 ± 15 ksi (800 ± 100 Mpa) | 24 ± 4% | 28 ± 3 msi (190 ± 20 GPa) | 35 – 45 HRC | 2100 °F (1150 °C) | 90 Btu in/(h ft2 °F/in) (13 W/m°C) | 7.6 – 8.4 x 10-6 in/in°F (13.6 – 15.1 x 10-6 m/m°C) |

Materials |

Stainless Steel 17-4 PH |

DESCRIPTIONExcellent weld-ability & corrosion resistance; Cost effective |

ULTIMATE TENSILE STRENGTH142 ± 7 ksi (980 ± 50 MPa) |

YIELD STRENGTH73 ± 7 ksi (500 ± 50 MPa) |

ELONGATION AT BREAK25 ± 5% |

MODULUS OF ELASTICITY25 ± 3 msi (170 ± 20 GPa) |

HARDNESS230 ± 20 HV1 |

MAXIMUM OPERATING TEMPERATURE~1022 °F (~550 °C) |

THERMAL CONDUCTIVITY97 Btu in/(h ft² °F/in) (14 W/m°C) |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

Stainless Steel 316L |

DESCRIPTIONExcellent weld-ability, corrosion resistance & ductility |

ULTIMATE TENSILE STRENGTH93 ± 7 ksi (640 ± 50 Mpa) |

YIELD STRENGTH77 ± 8.7 ksi (530 ± 60 Mpa) |

ELONGATION AT BREAK40 ± 15% |

MODULUS OF ELASTICITY |

HARDNESStyp. 85 HRB |

MAXIMUM OPERATING TEMPERATURE |

THERMAL CONDUCTIVITY |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

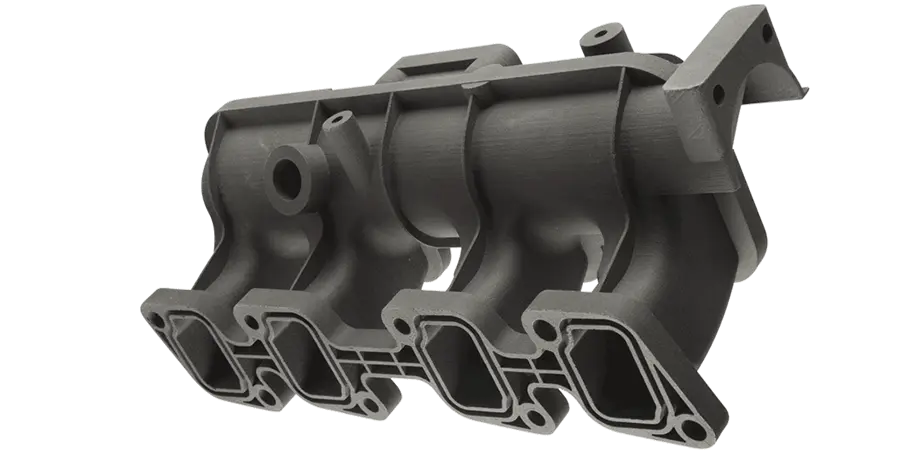

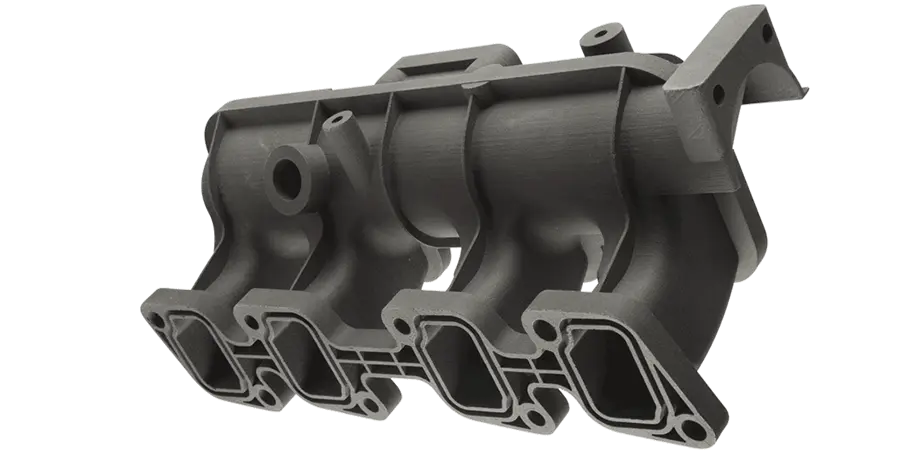

Aluminum AlSi10Mg |

DESCRIPTIONLow weight, high strength, & good thermal properties |

ULTIMATE TENSILE STRENGTH49 ± 6 ksi (340 ± 40 Mpa) |

YIELD STRENGTH36 ± 2 ksi (250 ±15 Mpa) |

ELONGATION AT BREAK1.5 ± 0.5 % |

MODULUS OF ELASTICITY |

HARDNESS120 ± 5 HBW |

MAXIMUM OPERATING TEMPERATURE |

THERMAL CONDUCTIVITY |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

Inconel 625 |

DESCRIPTIONHigh tensile, creep and rupture strengths |

ULTIMATE TENSILE STRENGTH130 ksi ± 7 ksi (900 ± 50 MPa) |

YIELD STRENGTH89 ksi ± 7 ksi (615 ± 50 MPa) |

ELONGATION AT BREAK42 ± 5% |

MODULUS OF ELASTICITY20.3 msi ± 3 msi (140 ± 20 GPa) |

HARDNESS~30 HRC (287 HB) |

MAXIMUM OPERATING TEMPERATURE~1200 °F (~650 °C) |

THERMAL CONDUCTIVITY |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

Inconel 718 |

DESCRIPTIONGood tensile, creep & rupture strength; Fatigue resistance |

ULTIMATE TENSILE STRENGTH142 ± 7 ksi (980 ± 50 MPa) |

YIELD STRENGTH92 ± 7 ksi (634 ± 50 MPa) |

ELONGATION AT BREAK31 ± 5% |

MODULUS OF ELASTICITY |

HARDNESS~30 HRC (287 HB) |

MAXIMUM OPERATING TEMPERATURE~1200 °F (~650 °C) |

THERMAL CONDUCTIVITY |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

Titanium Ti64 |

DESCRIPTIONBiocompatible; Corrosion resistance |

ULTIMATE TENSILE STRENGTH166 ± 9 ksi (1,150 ± 60 MPa) |

YIELD STRENGTH150 ± 10 ksi (1,030 ± 70 MPa) |

ELONGATION AT BREAK11 ± 2% |

MODULUS OF ELASTICITY16 ± 1 msi (110 ± 7 GPa) |

HARDNESS~400 – 430 HV (41 – 44 HRC) |

MAXIMUM OPERATING TEMPERATURE~660 °F (~350 °C) |

THERMAL CONDUCTIVITY |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |

Materials |

Cobalt Chrome CoCrMo |

DESCRIPTIONHigh tensile strength & hardness; Biocompatibility |

ULTIMATE TENSILE STRENGTH174 ± 22 ksi (1,200 ± 150 MPa) |

YIELD STRENGTH116 ± 15 ksi (800 ± 100 Mpa) |

ELONGATION AT BREAK24 ± 4% |

MODULUS OF ELASTICITY28 ± 3 msi (190 ± 20 GPa) |

HARDNESS35 – 45 HRC |

MAXIMUM OPERATING TEMPERATURE2100 °F (1150 °C) |

THERMAL CONDUCTIVITY97 Btu in/(h ft² °F/in) (13 W/m°C) |

CONDUCTIVITY COEFFICIENT OF THERMAL EXPANSION |