Hydroforming and rubber pad pressing dies or form tools are traditionally produced using a variety of materials and methods. Challenges with these methods include shortages of skilled labor, long lead times due to a backlog at the Computer Numerical Control (CNC) machine, high cost of raw materials, and high cost and lead times due to outsourcing. Stratasys 3D Production systems can help to alleviate these problems by producing Fused Deposition Modeling® (FDM) tools. FDM technology is an additive manufacturing process that builds plastic parts layer by layer, using data from CAD files.

FDM tools can help companies move from tool design to production in as little as a week. Many FDM tools can be completed in less than 24 hours with lights–out fabrication. Switching to FDM requires little change to current practices and procedures yet offers significant reductions in the time required to produce good parts. FDM reduces the cost for die production by 50% to 70% and reduces lead time by 60% to 80%. There is virtually no limit to the geometries that can be produced with FDM so it is often possible to implement design improvements in the end product. In fact, 3D Production Systems offer greater cost and lead time advantages with more complex and organically shaped parts when compared to CNC machining.

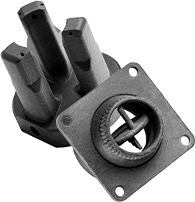

Stratasys offers several FDM materials for its line of 3D Production Systems that withstand the pressures required for hydroforming including acrylonitrile butadiene styrene (ABS) M30, polycarbonate (PC), and ULTEM 9085. The recommended forming pressure range for these materials is shown in the accompanying table. When dealing with rubber pad pressing, 3.0 inch (76.2 mm) tall FDM dies have been successfully cycled on 1000 ton presses using ULTEM 9085. Materials tested over FDM form blocks include aluminum alloys, stainless steels, titanium and nickel-based super alloys such as Inconel. Sheet thicknesses that have been formed successfully range from 0.016 inch to 0.100 inch (0.41 mm to 2.54 mm). These tools have lasted hundreds of cycles showing little to no signs of wear. In one case, a tool lasted 600 cycles without any problems. FDM tooling also offers a variety of other benefits. FDM tools are lighter and more ergonomic than traditional tooling, resulting in improved safety for the tool handlers and machine operators. Also, due to the natural porosity and lubricity of FDM, the number of cycles required to form trapped pockets can be greatly reduced and the need to lubricate sheet metal blanks can be eliminated. Further, the all digital process supports repeatable tool creation without need for an outside supplier and coordination of secondary tooling such as drill tools, trim tools and check fixtures. This makes it possible to potentially free up valuable storage space.