In an era of rapid urbanisation and ever-evolving architectural design, the construction and architecture industries are seeking innovative ways to meet growing challenges such as sustainability, efficiency, and unique design requirements. Amid this search, one technological advancement stands out as particularly promising: 3D printing. By integrating 3D printing technology into their design and production processes, architects and construction professionals can unlock numerous benefits, including rapid prototyping, streamlined production, and the ability to create bespoke, innovative structures that push the boundaries of traditional design.

In this blog post, we will delve into the myriad applications and benefits of 3D printing in architecture and construction, and examine Objective3D’s advanced solutions’ indispensable role in revolutionising these industries.

Rapid Prototyping for Enhanced Architectural Design

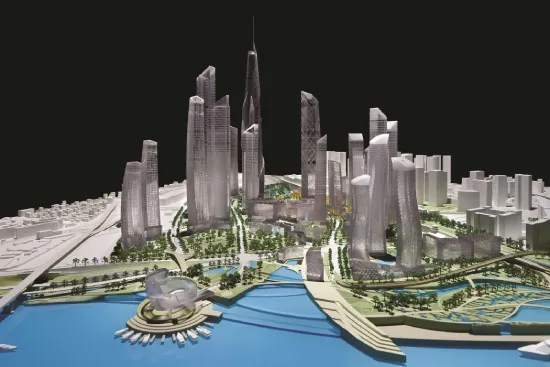

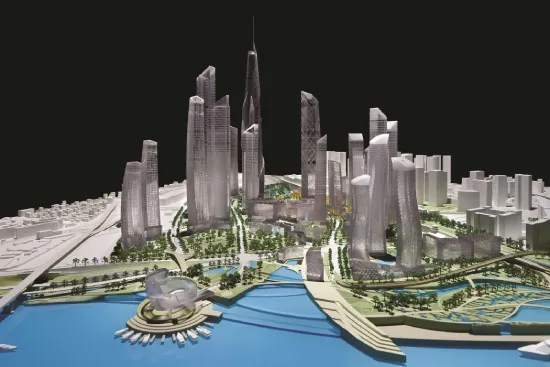

One of the most significant advantages of 3D printing technology in architecture and construction is its capacity for rapid prototyping. By enabling the swift creation of accurate architectural models, 3D printing allows architects and designers to expedite the design process, incorporating changes and refinements based on client feedback and practical considerations. Moreover, the ability to print relatively complex structures empowers architects to explore innovative design concepts and materials that may not be feasible with traditional building methods.

Objective3D’s advanced 3D printing solutions provide architects and construction professionals with the tools to harness the power of rapid prototyping, streamlining the design process and encouraging exploration of bold, unique architectural concepts. By embracing 3D printing technology, architecture and construction firms can achieve dynamic, efficient, and visually striking design outcomes, capturing the essence of modern architectural innovation.

Streamlining Production and Reducing Costs

Beyond design, 3D printing technology has the potential to streamline the production processes within the construction industry, leading to reduced costs and increased efficiency. Components and building elements can be 3D printed on-demand, minimising waste, material usage, and related expenses. Additionally, 3D-printed components can often be manufactured faster than those produced using conventional methods, accelerating construction timelines and reducing labour costs.

By leveraging Objective3D’s state-of-the-art 3D Printer and 3D Scanner Solutions, construction firms can benefit from the efficiencies and cost savings afforded by 3D printing technology. The adoption of 3D printing in construction results in more sustainable, cost-effective projects, transforming the industry’s approach to building and resource management.

Customisation and Complex Geometries

The design freedom enabled by 3D printing technology extends into the realm of customisation and the ability to create intricate, complex geometric structures. From bespoke architectural elements to innovative structural components, 3D printing allows architects and construction professionals to break free from the constraints imposed by traditional construction methods. This flexibility not only enables greater creative expression but also facilitates the implementation of advanced design principles, such as biomimicry or parametric design.

Objective3D’s cutting-edge 3D Printer and 3D Scanner Solutions empower architects and construction professionals to explore and realise intricate, personalised designs that challenge conventional architectural norms. The integration of 3D printing technology into architectural and construction processes unlocks a world of innovative design possibilities, enabling industry professionals to create structures that are as visually captivating as they are functional.

Supporting Sustainable Construction Practices

In an era when environmental impact and sustainability are paramount concerns, the adoption of 3D printing technology in architecture and construction presents a promising opportunity to mitigate the industry’s ecological footprint. By allowing for the precise, on-demand production of components and materials, 3D printing technology minimises waste and optimises resource usage. Moreover, the ability to create lightweight, optimised structures reduces the overall energy consumption and emissions associated with building materials and construction processes.

By providing access to advanced 3D Printer and 3D Scanner Solutions, Objective3D facilitates the integration of sustainability-minded practices into architecture and construction processes. This approach enables the creation of environmentally responsible structures that embrace modern aesthetics while contributing to a greener, more sustainable future.

Conclusion: Building the Future with Objective3D

As architects and construction professionals seek innovative solutions to enhance design capabilities, streamline production, and address sustainability challenges, 3D printing technology emerges as a powerful means of achieving these goals.

By embracing 3D printing technology, architects and construction professionals can unlock a world of possibilities, creating structures that are as functional and efficient as they are visually appealing and environmentally responsible. With the expert guidance and support of Objective3D, the future of architecture and construction can be built on the foundation of innovative technology, sustainable practices, and groundbreaking design.

As a leading provider of Stratasys, GE Additive, Lithoz, and Artec 3D Printer and 3D Scanner Solutions in Australia and New Zealand, Objective3D is well-equipped to support the architecture and construction sectors in harnessing the full potential of 3D printing technology. Whether you are looking to streamline your production processes, improve design accuracy, or explore new frontiers of innovation, our team of experts can help you harness the full potential of 3D printing technology. Let us help you unlock the power of 3D printing, and take your architectural and construction projects to the next level. Contact us today to schedule an appointment!